M&G Construction and Driveways is a Zimbabwean construction company that has proven that there is no substitute for experience. The construction company was incorporated in May 2017 by Tawanda Muindisi and Potifa Gosho who have a combined experience of 45 years in the construction sector.

M&G Construction and Driveways specialise in structural brickwork, plastering and painting, driveways and landscaping, concrete roof tile installation, and providing turn-key solutions for setting up concrete brick and tile plants. The company has a team of highly qualified and experienced technical staff who are capable of implementing large-scale projects.

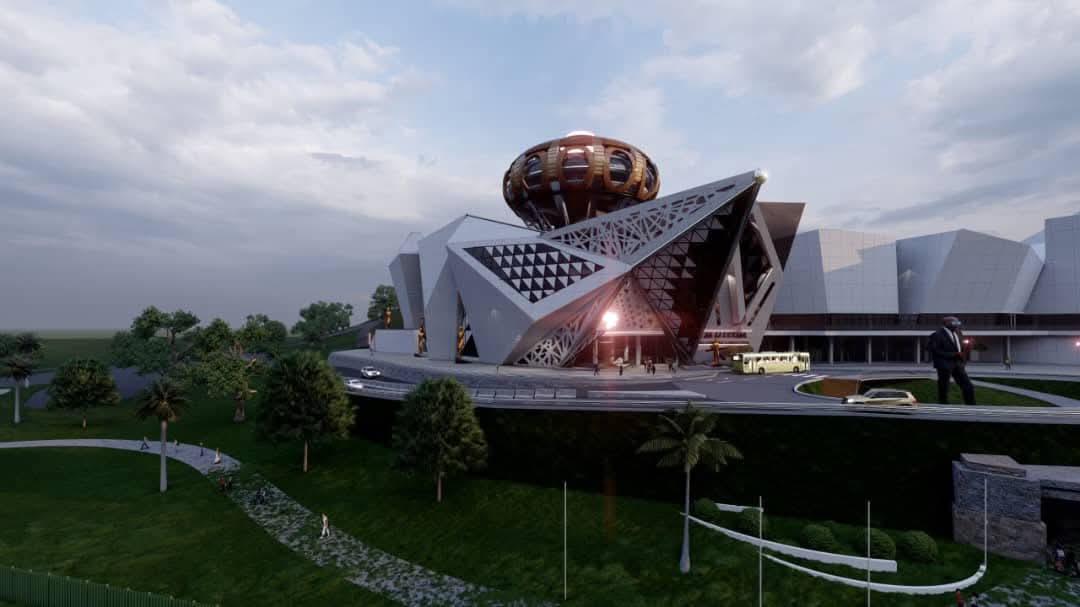

M&G Construction and Driveways are proud to be the paving and kerbstone subcontractors for the magnificent recently launched Zimbabwe Electricity Industry Pension Fund’s (ZEIPF) Marondera Megawatt Mall. In addition, the company has been involved in a number of upmarket cluster homes in Harare. M&G Construction and Driveways have done construction-related works for a number of listed companies including Masimba Holdings for paving work and the Victoria Falls Sawanga Mall, a Zimre Properties investment,

If you are looking for a reliable and experienced construction company in Zimbabwe, then M&G Construction and Driveways is a great option.

The company has a proven track record of success and a team of experts who can deliver high-quality results.

M&G Construction and Driveways’ offices are located at 23 NRZ Yardmaster Complex Corner Kenneth Kaunda and 4th Street in Harare. They can be reached on the mobile numbers 0774 300 425 and 0773 366 071. On email, they are accessible either at potifag@gmail. com or tawanda. muindisi@gmail. com.

The scope for the construction of prefabricated structures is limitless. The buildings can be for accommodation (housing or dormitories),

or commercial structures (offices). The usage may also extend to mines, farms, and schools as well as emergency accommodation in the aftermath of disasters.

However, it is advisable to consult the municipality or local authorities regarding by-laws relating to the construction of structures using precast building materials.

Prefabrication is a method of construction that involves assembling pre-made components off-site and then transporting them to the construction site for final assembly.

This type of construction method has distinct advantages over on-site brick and formwork such as:

Durability

The case for using precast building material is the fact that the concrete panels are particularly strong and durable. This is because there are instances where the components have to be transported over a long distance to the construction site.

Faster construction

The desired build can be done in a few days or weeks depending on the size and scope of the project. When a project involves slotting pre-manufactured panels together or covering a pre-assembled frame, construction times are reduced immensely compared to traditional building processes. The casting of panels can happen in tandem with foundation works. Elements such as insulation can also be woven in, instead of being added in the later stages of construction.

Less ambient risk factors

Off-site manufacturing of construction materials reduces the risk of on-site delays due to inclement weather or related environmental factors. Moreover, each component is made to identical standards and finishing thereby eliminating the chances of compromising the quality and lifespan of the material.

Pre-construction quality control

The manufacturing process ensures prefabricated components can be individually checked for quality standards before dispatch to the site. Also, relevant safety protocols can be verified before construction begins. Less risk of on-site accidents Fewer people undertaking less work in less time without the hustle and bustle of delivery trucks and earthmoving machinery reduces the risk of on-site accidents. This in turn waters down the delays, paperwork and repercussions that may follow in the event of an incident.

Simplifies construction processes and timelines

Prefab construction projects need lesser oversight and fewer managers to supervise on-site teams. It also requires less specialist training in comparison to stone masonry. Planning is more accurate as well considering that timelines are shorter and works can be completed in contingency time.

Environmental benefits

Prefabricated construction material is a boon for the environment considering that there is minimal construction waste. As the construction industry is looking more and more to reduce the overall ecological footprint, some prefab manufacturers are leaning towards using either eco-friendly, recycled matter, or a combination.

Lower costs

Prefabrication construction projects use less manpower and building material hence total costs are greatly reduced. Additionally, standardised panel measurements mean off-the-shelf plans and schematics are often available, which results in saving money on architects’ fees. Similarly, prefabricated materials are mass-produced and bought in bulk, bringing economies-of-scale savings.

Extensions are easier to attach

Unlike brickwork, extensions can quickly and cheaply be made using precast material. Adding a modular extension is largely more cost-effective than relocating to new premises or acquiring an additional site to accommodate expansion. Dismantling and recycling are easier Materials that already bear a low ecological footprint are often among the easiest to recycle. Being able to reuse or repurpose them once the building reaches the end

of its lifespan is both cost-effective and environmentally friendly. Disassembly also avoids the complexities of demolition or specialist intervention by simply reversing the steps from the original construction process. On the flip side, it is important to note that upfront costs can be high for prefab construction.

This is because the components must first be manufactured and then transported to the construction site. Also, prefabricated components may be limited in terms of customisation, which can restrict the available design options. Prefabrication construction is dependent on specific needs and requirements and it is a faster, more efficient and environmentally friendly way to build and may be considered as an option.

Text by Perry Kaande

Photos by Potohaus

Read our magazines here