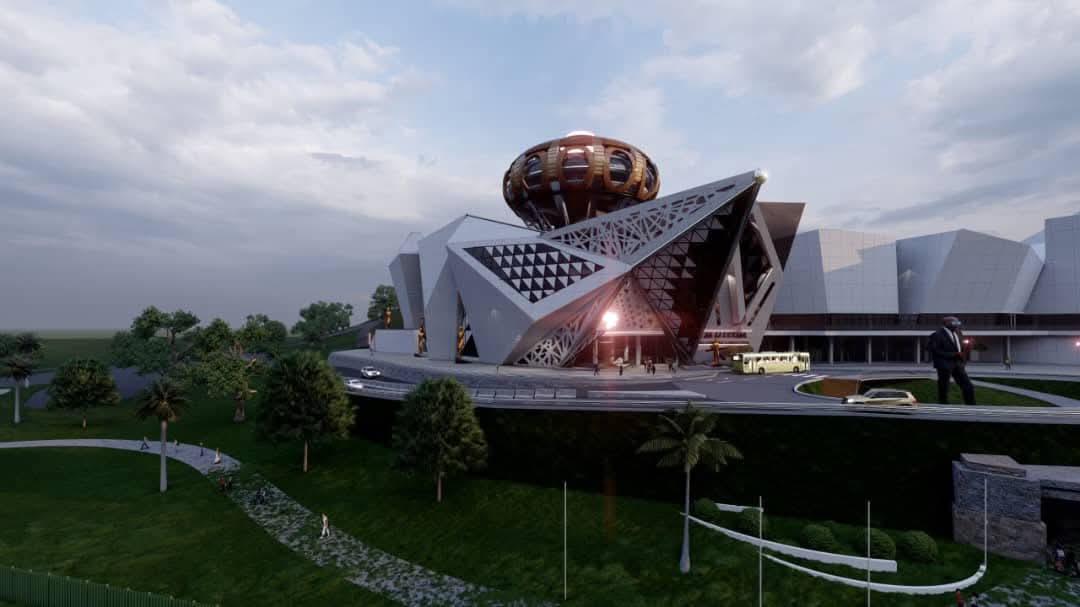

WE like to work openly with our customers and suppliers so that you, the customer, gets the best possible build for the best possible price. We pride ourselves on our quality of fnish and believe this is unmatched in Zimbabwe. To achieve this we like to discuss your requirements pragmatically so that you end up with a product that suits your requirements and budget. We proactively take ownership of any problems, queries or confusion by dealing with them face-to-face as soon as feasibly possible, regardless of who it is or where they are located. We have found that this attitude cuts down immeasurably on costly delays caused by late decisions, particularly on complex builds like shopping centres, where the design is changed to suit changing tenants and architecture.

With the experience we have gained in the region we understand how things work and quickly adapt to get the product delivered and erected on time. Harare is centrally located in southern Africa and as such we can be in either Johannesburg, Lusaka or Tete within hours. Our strength lies in the fact that we are able to work fuidly with the customer and build teams, promptly dealing with any problems or variations as they occur so that the project is completed to specifcation within the stipulated timeframe. Our more recent larger projects have been for customers such as: First Quantum Minerals (Zambia), Waterfalls Mall (Zambia), Pemba Shopping Mall (Mozambique), Zambezi Junction (Mozambique), Nampula (Mozambique), Bathroom Boutique (Bulawayo), Golden Leaf Tobacco (Harare) and Althorne (Harare) .

Our steel structures are fabricated in Harare, Zimbabwe, in our 6000m2 facility which is serviced by overhead cranes and forklifts, with standby generator backup for power outages. Our factory can produce 200 tonnes of fabricated steel per month to cater for project deadlines. Our clients can be assured that we have the capacity, skills and systems to take on any job, large or small. We have the cutting, welding and jig equipment to manufacture fabricated I – beams, castellated beams, heavy rolled plate structural tubes, conventional angle iron lattice trusses and portal I-beam structures. All structures are exported with a COMESA and/or SADC Certifcate where appropriate. Given the ever-changing steel supply and pricing within the region, we are fexible and quick to take up new, more innovative designs using the most cost effective materials available at the time.

We see this as a challenge and embrace the experiences and lessons learned from different fabrication methods and materials. Installation and erection of our structures is undertaken by our skilled steel erection and roofng teams using our own cranes and equipment. If the installation is to be done by the customer, we place a skeleton crew on site to assist with understanding the installation plans and component identifcation, along with early identifcation of possible errors or omissions so that work stoppage is kept to a minimum. (Every single component is individually marked and gridreferenced on the installation plans by our detailing software

With our in house Tekla BIM (www.teklabimsight.com) detailing facilities and quality control procedures, we stand out in our industry, making Superstructures the frst choice for your fabrication project. This highly sophisticated program enables us to visualise the entire steel structure as a 3D model and because it is based on parameterised technology, any subsequent changes once the fabrication has started may be done relatively quickly. A 3D model can be viewed on any computer and approved by the client before fabrication commences.

What is more, a computerised model allows elimination of any material clashes. Potential design issues can be easily visualised, explained and resolved – reducing project costs. When we generate quotations, the proposed structure would have already been drawn and a bill of quantities generated so that our quotes are accurate and frm for the duration of the project without any surprises half-way through the build. If there are any changes to be made these are treated as variation orders at agreed rates used on the initial quote. We believe in an open book policy so everyone can be on the same page and you are able to accurately cost any alterations you may want to make.Recently we have become involved in building shopping centres in Mozambique and Zambia. These are signifcantly more complex than typical warehousing where attention to detail is paramount and as such we have become quality conscious and pay particular attention to ensuring frst class installation and fnishing. We guarantee that Superstructure sheds are fnished to the highest standard.

THE NEW SEAMLOK 745 CONCEALED FIX ROOFING SYSTEM

AFTER 25 years of roofng experience using locally available roofng, we decided that there were better systems and have subsequently invested in the latest concealed fx roofng machine. This roofng system is ideally suited to the larger span buildings.

WHY SHOULD YOU USE THE SEAMLOK 745?

- The roofng fasteners do not penetrate the roof sheeting, thereby signifcantly reducing the potential for leaks especially when the roof is getting older.

- The Rolling machine is a mobile unit enabling the Roofng coil to be rolled on site. This means that each roof panel is rolled to the length of the roof i.e. if your entire roof is 24m wide by 30m long we would then cut the roof panels to 24m length. There are no horizontal overlaps between the sheets and subsequent wastage and galvanic rust between the overlaps. There is also less chance of the sheeting getting damaged in transit to site.

- The greatest advantage of a standing seam metal roof is that the seam is higher than the roof panels and the seam is mechanically crimped as the sheeting is laid, further reducing the chances of leaks. • Due to the nature of this type of roofng system even with a 2 degree pitch the roof will still perform better than more common profles.

- We can roll coil from both South Africa and offshore in thicknesses ranging from 0,5mm— 0,6mm. This enables you to choose your colours from Galvanised Steel, Zinc alume, Chromadek or Colour Bond.

- Roof sheets accurately cut to length by cnc guillotine.

PRODUCT

The SeamLok 745 is a trapezoidal standing seam concealed fx roof sheet Material The base material used is 925mm chromadek or colorbond coils in 0.5mm up to 0,6mm.

Side Lap Joins Sheets are joined with a 360degree double lock rolled site seam making for a extremely weatherproof seal.

Fixing The sheeting is fxed using concealed clips which are folded within the seam. Purlin Spacing 0.58mm Chromadek = 1.8m 0.55mm Zincalume = 1.8m 0.5mm Chromadek = 1.4m 0.47mm Zincalume = 1.4m Gradients 2% and upwards Lengths

Typically up to 25m but can increase to 50m Colours Standard Chromadeck Colours, unpainted Galvanised, Zincalume and standard Colorbond.