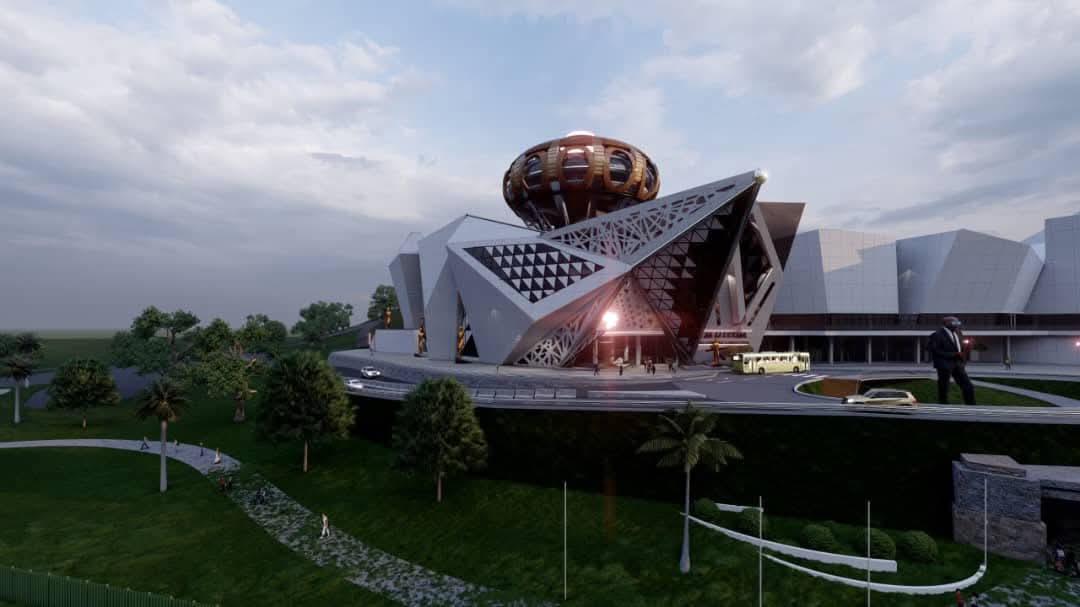

Today City Glass are the leading suppliers and distributors of a wide range of glass products in Zimbabwe and the region. They have maintained their position by keeping up with the rapidly changing developments and demands in the glass industry. Glass, in all its different forms, has become an increasingly popular material. Businesses involved in construction and décor, including architects, engineers and interior designers, are constantly demanding newer and more complex glass solutions. City Glass has kept up with international trends by investing in state of the art machinery that meets global standards.

The LISEC fully automated laminated glass cutter provides Austrian technology, precision and convenience at its best. The machine can cut laminated glass from 6,38mm up to 20,38mm with outstanding accuracy. Glass sheets are manually placed on the cutting bed where they float on a cushion of compressed air allowing the sheets to be moved easily. A skilled and trained operator enters the dimensions and specifications required into the computer which then detects the sheets dimensions in the x and y directions and optimises the cutting list to fully utilise the sheet with the least waste.

The machine precisely cuts the glass and at the same time melts the laminate between the two glass sheets. The operator can then easily move the scored glass sheet to a flipping device which snaps the sheet along the desired line. The machine reduces costs for customers by optimising the cutting list thus reducing waste and it virtually eliminates breakages associated with manual cutting. The machine can cut up to 300 sq. m of laminated glass per day making the processing time much faster. City Glass processed the glazing for the Joina Centre, one of the many high rise buildings in town. This new equipment would certainly have made the project easier and quicker.

The Italian made Bavelloni NRG 330 glass processing machine allows City Glass to meet the increasingly demanding specifications required by the construction, engineering and interior décor industries. It’s a CNC (Computer Numerical Control) machine designed to cut monolithic float glass in a variety of complex shapes, as well as drill holes of various dimensions in precisely the correct place, polish the edges of the cut glass and bevels.

It’s ideal for a number of applications including frameless glass for shower cubicles, balustrades, shop fronts, curtain wall partitioning, decorative mirrors, kitchen splash backs and table tops. The machine can cope with bigger sheets and heavier glass than could previously be easily processed manually, and complete the job in a much shorter time with much less wastage. Programming Operators have engineering degrees and were sent to South Africa for specialised training as well as being trained locally by the Italian team who installed the machine and periodically come for servicing.

In addition to these two highly advanced pieces of equipment City Glass also has a Roller Hearth Toughening Furnace which processes ordinary float glass of various thicknesses into tempered glass. The furnace rapidly heats the glass to temperatures of up to 700 degrees creating a safety product which enables the glass to be used for showers, balconies, sliding doors, furniture and glass curtain walling. The glass is 5 times stronger than before the tempering.

City Glass have maintained their position at the cutting edge of glass processing and distribution through constantly investing in the latest technology, relevant staff training and excellent customer service. City Glass are happy to advise customers – architects, furniture manufacturers, shopfitters and interior designers – about the best products available to suit every application.