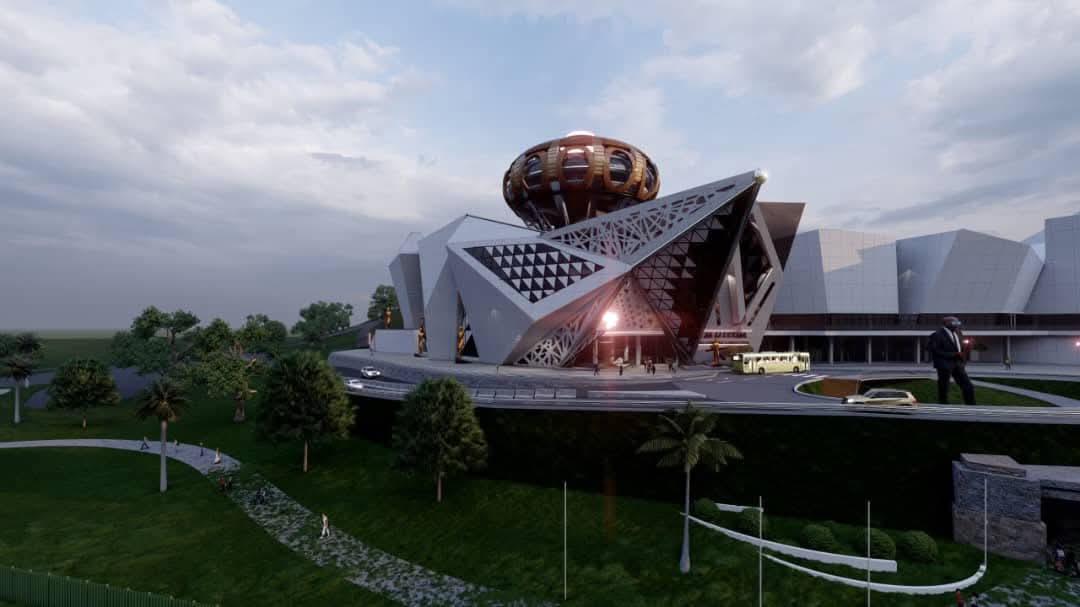

The iconic Harare Showgrounds is set to undergo a dramatic transformation. Terrace Africa is develop-ing the Greenfields Mall, a state-of-the-art shopping destination scheduled to open its doors before the end of the year. This ambitious project promises to redefine the city’s retail landscape.

With a 10,000m² of Gross Lettable Area (GLA), several leading construction companies have been roped in to spearhead the project and among them is steel infrastructural experts Brown Engineering Group.

Shepherd Tshalibe, a site manager with Brown Engi-neering Group spoke glowingly about one of Harare’s most exciting projects.

“Greenfields Mall is an incredibly exciting project for us at Brown Engineering Group,” says the site man-ager. “It’s a transformative initiative for Harare, not only as a retail destination but also as a hub for community gatherings and agricultural showcases. The scale of the project, coupled with the intricate steelwork involved, presents a unique challenge that we’re thrilled to undertake.”

He said that the estimated weight of the steel struc-ture being installed for the mall is about 205 tonnes, making this project a massive undertaking.

Talking about the type of steel being used in the construction, and why this specific type was chosen, he said: “We are installing lattice trusses inside the mall. Using square tubes as columns for the canopies and rectangular sections for the canopy trusses. For the anchor shop entrance, we used I-beams for the columns and trusses”.

Lattice trusses are triangular structures that provide exceptional strength and rigidity to the shop’s roof, efficiently distributing loads and maximizing space, square tube columns are sturdy columns that offer excellent load-bearing capac-ity and aesthetic appeal, supporting the weight of the canopy and ensur-ing structural integrity.

On the other hand, rectangular section trusses provide optimal strength-to-weight ratio for the canopy, ensuring it can withstand various loads and weather con-ditions and I-Beams are versatile beams highly efficient in supporting heavy loads, making them ideal for both columns and trusses in the shop’s structure.

They contribute to the overall strength and stability of the building. The dimensions of the largest single steel component being installed on the project is UB305X165. The scope of the project has necessi-tated the use of specialized equipment such as rigid cranes with a 20-ton capacity to lift and install the steel components.

The steel installation phase of the project started in March this year and should be completed by the end of November. More steel will be installed early next year, according to the site manager.

The steel structure contributes to the overall design and aesthetics of the mall. Steel is contributing much on the front façade, and to make all the canopies in the front facade. As for most of the steel, it will be covered by ceiling inside the mall.

Steel construction has its added advan-tages over other materials like concrete or wood due to its qualities of durabil-ity, affordability and low maintenance costs.

Despite the project progressing on time, there have been a few challenges encountered during the steel installation process, however these have all been attended to and addressed profession-ally.

“Setting out is the biggest challenge on most steel projects, sometimes HD bolts can be cast at wrong positions. But for this job, we managed to avoid the challenge by having surveyors check all these HD bolts and cast-in plates prior to concrete pouring,” said Tshalibe.

These steel structures are in addition being used for anchoring fire lines which run through the ceilings.

The steel structure contributes to the overall structural integrity of the mall as steel offers over 550MPa, which holds loads like compression, tension, seismic, wind

loading and so forth.. The steel structure contributes to the seismic resilience of the mall to a larger extent.

Tshalibe in addition highlighted the innovative techniques and technology currently being used in the steel instal-lation process, referring to Cranes and Chemical anchoring.

The development of the Greenfields Mall comes on the back of real estate experts observing that the retail industry is undergoing a significant transforma-tion, with a notable shift in preference towards suburban shopping centres. This trend is particularly evident among larger retail groups and premium brands. Conversely, non-retail busi-nesses, such as corporate offices and tech firms, are gravitating towards office parks.

Several factors are driving this shift. Suburban shopping centres often offer ample parking, convenient access, and a more relaxed shop-ping environment. This appeals to consumers, especially families, who prefer to avoid the hustle and bustle of city centres. Beyond this reality, suburban locations can be more cost-effective for retailers, reducing overhead expenses and improving profitability.

Similarly, office parks provide a modern, professional setting for businesses. They offer amenities such as high-speed internet, onsite dining, and fitness facilities, which attract and retain top talent. Moreover, office parks often have dedicated green spaces and recre-ational areas, promoting employee well-being and productivity.

Several high-end brands and major retailers have already committed to opening stores at Greenfields Mall, including KFC, Café Nush, Liquor Supplies, TV Sales, First Capital Bank, Spar, Roco-Mamas, Spur, and The Smokehouse. This influx of renowned brands underscores the mall’s poten-tial to become a premier shopping destination in Harare.

Paving of the spaces around the mall has been carefully undertaken by B.D. Stodart Machinery while RadX Construction is the main contractor.

As the project nears completion, Brown Engi-neering Group is proud to contribute to this transformative development. The steel structure, a show of engineering excellence, will be a key component of Greenfields Mall, shaping the city’s retail landscape for years to come.