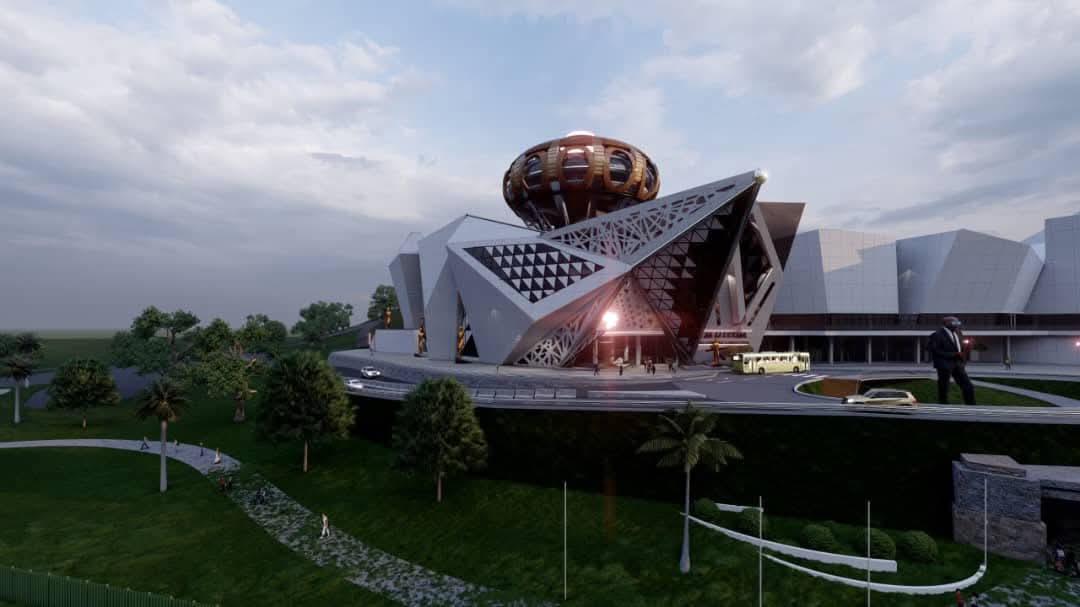

After decades of operation on Seke Road, Rooneys Hire Services will, in the near future, be relocating to a new state-of-the-art head office along Airport Road. Currently under construction, the ambitious project spans 32,000 square meters, and is progressing very well.

Despite the vast size of the land, the building utilization will be relatively modest at 23.28%, amounting to approximately 8,000 square meters, according to the site manager. This strategic decision ensures efficient use of space while accommodating the specific needs of Rooney’s Hire Services.

Rooneys is currently experiencing constrained space at their several locations they are operating from along Seke Road and now they seek to find a long-term solution to the challenge.

When the Structure and Design Magazine team visited the site, trusses were already in place, forming the skeletal framework of the building. The focus has now shifted to reinforcing the structural integrity, with workers diligently installing lifting columns and compression braces. These play a crucial role in connecting the columns and providing essential support, ensuring the building’s stability and durability.

The process of installing trusses is another critical component of the warehouse’s framework. Brown Engineering, a key contractor for the project, has been instrumental in the early stages. The local manufacturing company has expertly fabricated these trusses, as well as taking on the rigging responsibilities.

This meticulous process involves carefully positioning and securing the trusses in place.According to site managers, the rigging phase was expected to be completed within a week. The hard work and efficient efforts of Brown Engineering are vital in ensuring that the warehouse construction remains on schedule.

The project encompasses four distinct buildings, each showcasing Brown Engineering’s engineering prowess. The main storage warehouse measures 138 meters by 30 meters, while the maintenance warehouse is slightly smaller at 102 meters by 20 meters. The administrative building is 48 meters by 18 meters, and the canteen is approximately 44 meters by 18 meters.

The main storage warehouse was meticulously marked, setting the stage for the structural construction to commence. The steelworks involved pouring concrete blinding to create a solid base for the foundation steel.

This foundation steel is strategically placed to ensure that the structural loading is evenly distributed to the ground. The team then proceeded to set the steel reinforcement for the basements, including stutter piles for the step columns that will support the structural steel above.

After this stage, concrete bases were poured to a specified depth of 400mm. The step columns, which are crucial for holding the structural steel, were then prepared with meticulous precision to ensure the building’s structural integrity.

The structural steel itself was prefabricated at Brown Engineering and brought to the site for installation. To secure the prefabricated steel, bolts were set in place, requiring precise linear measurements and diagonal accuracy to the millimetre. This attention to detail is essential for ensuring the structural integrity of the entire building. Once the bolts were accurately set, the structural steel could be installed without any problems.

The foundation used 30 MPa concrete to securely hold the structural steel, but the specific concrete strength may vary depending on the building’s size and weight. Engineers carefully design the foundation to accommodate the structural loading and ensure its long-term durability.

As of the time of this publication’s visit, the construction team was working towards reaching the fifth-placing beam, which is the centre of the storage warehouse. This will allow them to start superstructure works

from the back while simultaneously completing the front section.

The process involves further erecting steel columns, bracing, compression bars, compression beams, and trusses. Before finalizing the bracing, the team carefully checks the levels to ensure accuracy.

With this massive project, Brown Engineering is once again showcasing its huge capacity to help transform the infrastructural landscape of Zimbabwe, one project at a time. And they are doing it in style!

From: S&D ISSUE 69