Although the Brown Engineering Group has a wealth of experience in many diverse areas of the engineering, construction and manufacturing industries the Gwebi River Bridge is their first vehicle road bridge.

The bridge was commissioned by the Ministry of Transport and Infrastructure Development as part of the dualisation of the Old Mazoe Road from the Westgate roundabout to the Mvurwi turn off.

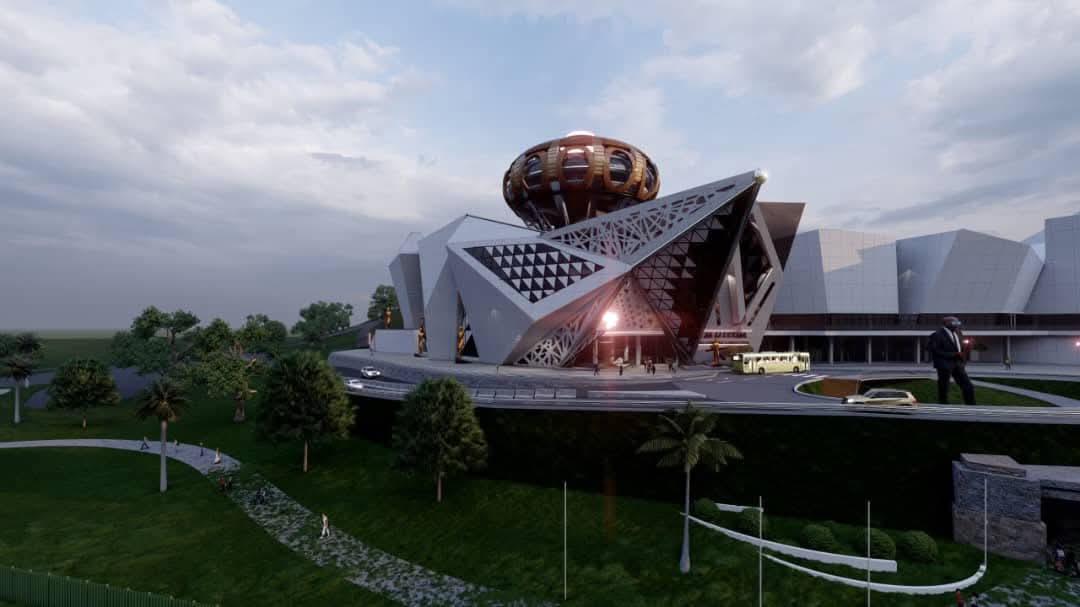

It’s part of the government’s drive to develop infrastructure in line with the policy framework for Vision 2030.

It will improve travel time, increase motorists’ safety as well as providing easier access to the New Parliament.

The bridge was designed by ZICAD

Engineering Consultants, leaders in the field of Mechanical, Electrical and Project Management Services (MEP), with the Ministry of Transport and Infrastructural Development as the client.

The design follows the specifications set out by the Ministry of Transport and Infrastructure Development Part JD which deals with bridge construction.

Brown Engineering Group was selected to supply the steel works. Exodus and Company are constructing this section of the new dual carriageway and are also doing the civil works for the bridge.

The bridge has a 20-meter clear span above the river. The steel girders, which were custom manufactured and fitted by Brown Engineering Group, sit on top of the massive concrete wall type abutments on either side of the river built by Exodus and Company.

The steel girders are fixed to the abutments by elastomeric bridge bearing pads of steel and rubber which let the steel shift slightly to accommodate expansion and contraction.

There is a 40mm gap at either end of the girders to allow for movement.

Brown Engineering custom manufactured the girders in three sections welded together to create a kind of I-beam 1.3 meters high.

The extra-long welds, using the sub-arc welding technique, were particularly difficult and demanding to achieve. Each girder is made up of two sections – one 8 meters long and one 12 meters long – to make up the 20-meter span.

The welding was inspected and approved by two independent engineering companies, ZICAD and Probitas Engineers to verify and approve their structural integrity.

Between the steel girders Exodus and Company will install pre-cast concrete panels fixed to the shear lugs which Brown Engineering Group manufactured on their girders.

The lugs function to fix the concrete panels to the steel. On top of the precast panels will be a concrete deck with a final asphalt layer on top.

Each of the steel girders manufactured and fitted by Brown Engineering Group weighs just over 17 tonnes.

They were manufactured in two parts, comprised of 12 meters and 8 meters, to form the required 20-meter span, as well as for ease of transportation and handling.

The longer section weighs 10 tonnes and the shorter section 7 and a half tonnes. They were loaded onto Brown Engineering Group’s truck using a 20 tonne crane and a 160 tonne crane on site to lift the girders in to position.

Because of the enormous weight involved the girders were transported one at a time. Once on site they were assembled with 20mm splice plates and M30 bolts with a total of 106 bolts on each girder.

Brown Engineering Group purchased a special electronic Newton-Meter Torque wrench to guarantee the bolts were correctly tightened to the highest specifications.

The girders were painted with corrosion resistant epoxy to ensure an extended life span of at least 100 years. The design also includes future proofing the structure to accommodate climate change issues like flooding or extreme weather fluctuations.

The procurement and fabrication took one month and the installation took a week. Once completed the bridge will have concrete stanchion parapets and steel railings for safety, supplied in conjunction by Brown Engineering Group and Exodus and Company.

There will also be a single lane for pedestrian access.

Although this will be Brown Engineering Group’s first vehicle road bridge they have provided the pedestrian bridge at Eastgate Mall.

They are currently supplying the steel work for many warehouses across the country, and the continuing development of a range of upmarket shopping malls.

They are also involved with the construction of the exciting new waste-to-energy project undertaken by Geo Pomona Waste Management, so their portfolio is impressive and diverse.

Text by Michael Nott | Photos by Fotohaus

From S&D ISSUE 67