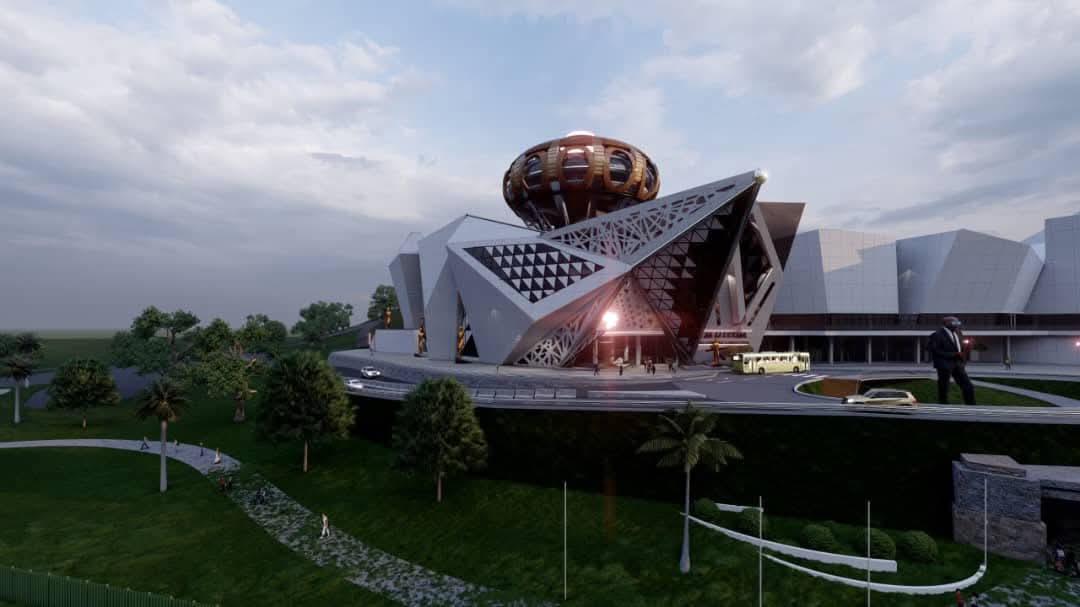

Geo Pomona Waste Management (Private) Limited, an initiative founded under the vision of His Excellency President ED Mnangagwa, is converting waste into energy, with plans to replicate its successful model across other cities and provinces in Zimbabwe, and thereafter into the SADC region and Africa. Located at the Pomona Landfill, Alpes Road, North Harare, and approximately 13 km northeast of Harare CBD, the project was established as a Joint Venture Concession Agreement between the City of Harare and Geogenix BV (a Netherlands-based company). CEO and Executive Chairman, Dr Dilesh Nguwaya, leads the company whose project’s vision is “to be Southern Africa’s first, best, and most efficient waste management and power generation project, and to adopt a ‘zero waste-to-landfill’ approach.”

With a capacity to incinerate approximately 1,000 tonnes of solid municipal waste daily, the company’s waste-to-energy plant is expected to produce between 16 to 22 MW of electricity, which will be injected into the national grid (ZESA). Geo Pomona Waste Management is therefore significantly contributing to Vision 2030 by simultaneously providing clean energy and fostering a clean and safe environment essential for an empowered and prosperous upper-middle-income society.

The waste management pioneers utilise Innovative Technologies and Best Practices from local and international experts to create a healthier and safer environment for communities.

Their forward-looking technology solutions aim to create a cleaner, greener, and more sustainable environment, while their best practices draw on the best from both local and international experts to ensure that their waste management solutions are effective, sustainable, and innovative.

In their ongoing quest to keep abreast of global standards and raise the efficiency standards of Harare’s waste management system, they recently contracted local and regional steel structure

installation company Brown Engineering to work on a new garage-cum-workshop for their newly acquired trucks.

The appropriately sized members were used for load bearing capacity, and the structure was painted with two coats of corrosion resistant paint. The fabrication of the steel components were done at Brown Engineering, and there were no logistical challenges faced in transporting and rigging the large structures at the waste management company site. Overall working timelines were

efficiently managed, spanning from 13 to 28 August 2025 for everything including the three major components of fabrication, installation and project handover to the client.

Another steel installation was for a new stores shop at the same premises. Both structures have significantly enhanced the broader outlook of the waste management facilities. Given the complex nature of a waste management facility, the project’s engineering and design specifications accounted for factors like corrosion resistance, heavy load-bearing capacity, and facility-specific ventilation requirements. They used whirlybirds for better ventilation and translucent sheets for natural lighting. For the specialized rigging techniques, they made use of a 20-tonne crane

to install the structure. The rafters were assembled on the ground and then safely hoisted with the crane, ensuring efficiency and precision during erection.

Brown Engineering’s experience in other heavy industrial structures prepared them for the unique demands of a modern waste management facility project like this one. Success of the project

was possible due to Brownm Engineering’s versatility in delivering various structures, whether industrial, agricultural, mining or residential to clients. Proper research from their research

and development team about waste to energy structures was useful in the design and installation of these structures.

The project was even more beneficial for the local communities as more than 40 jobs were created from fabrication to installation stages, over and above the already hired employees. Spearheading the project were local talent involved from design to implementation stages and through these technically demanding processes, the teams ensured the local steel structures seamlessly integrated with the cutting-edge waste processing equipment. As required in these projects, all quality control and safety standards were strictly adhered to during the fabrication and on-site erection of the steel structures, especially given the site’s environment. The fabrication was mainly compliant with SANS and British codes, while the installation was mainly in line with general building guidelines.

The successful completion of these steel structures will assist in making the waste management operations run seamlessly from waste collection in the city to processing the waste. As for Brown Engineering, working with yet another global standard company has added further weight to its huge reputation in the design and manufacture of steel structures used across industries in Zimbabwe and the SADC region.