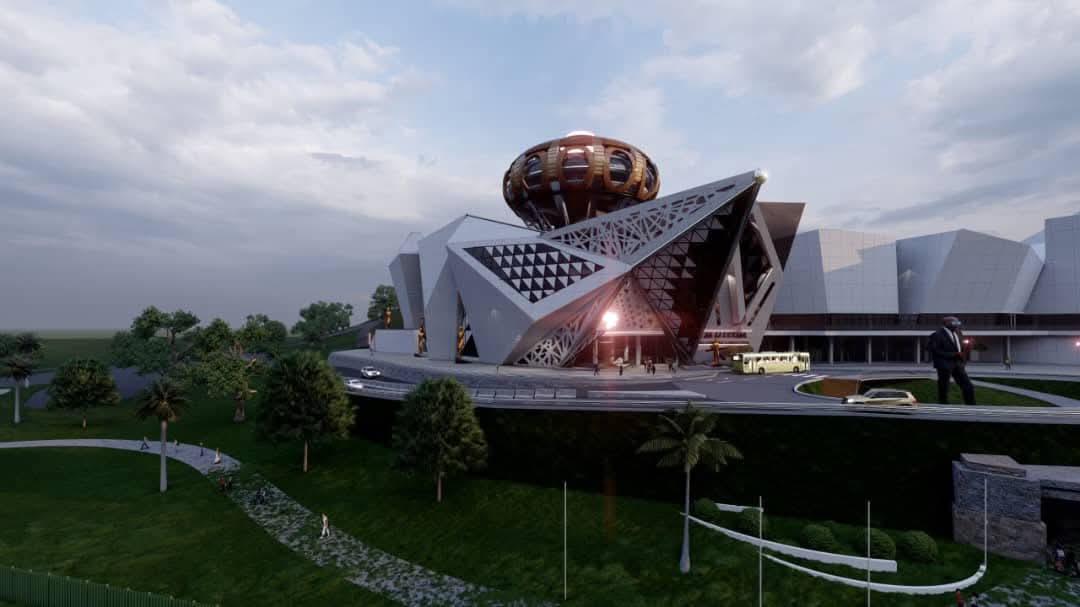

Brown Engineering Group, a Zimbabwean leader in diversified construction, recently joined forces with Total Property Solutions (TPS) to deliver a transformative new facility for Dulux in Harare. This impressive warehouse consolidates Dulux’s main manufacturing and distribution centre under one roof, streamlining operations and boosting efficiency.

A Strategic Move for Enhanced Efficiency Previously reliant on leased warehouse space, Dulux’s decision to unify manufacturing and warehousing offers a multitude of benefits. Streamlined logistics minimize transportation needs, while centralized inventory management grants Dulux greater control over their stock. This strategic move also reduces costs associated with maintaining separate facilities.

Safety and Functionality at the Forefront

The new warehouse embodies a thoughtful integration of functionality and safety features. Raw materials used in the manufacturing process are secured under a large overhanging roof, maximising fire safety. An additional layer of protection comes from a comprehensive fire-retardant system installed throughout the warehouse and outdoor storage area. The fire repression system was installed by Lesop Fire.

A Well-Designed Solution

Designed by Steve Norton to meet Dulux’s specific needs and site constraints, the warehouse boasts a generous 4,900 square meters of storage space. The interior layout prioritises efficiency, minimizing support columns to provide unimpeded access for forklifts and maximising storage capacity.

The vast interior space, spanning roughly 54 x 63 meters, features a visually striking element: interlocking tri-frame trusses designed by Brown Engineering. These innovative trusses elegantly span the exceptional roof width, creating a sense of spaciousness.

Beyond functionality, the warehouse offers a well-lit and pleasant working environment. The 10-meter height allows for additional vertical storage, while large roller doors at either end facilitate efficient loading and unloading. Translucent wall panels bathe the interior in natural light, fostering a productive atmosphere.

The structure itself is a blend of modern materials, featuring a steel skeleton with brick infill at the base, Chromadek sheeting for walls and roof, and strategically placed overhead electrical lighting. Notably, Dulux’s in-house construction team provided most of the electrical fittings. The exterior allows access for smaller vehicles like pickups and trucks.

Great team effort in the Project’s Success

Shepherd Tshalibe, a seasoned project manager at Brown Engineering and the super-efficient Brown Engineering Group TEAM, played a pivotal role in the successful completion of the Dulux Paints warehouse. The Brown Engineering team oversaw the design, fabrication, and installation of the steel roof trusses and other structural components. Tshalibe’s expertise and experience ensured that the project remained on schedule and within budget.

Collaboration Leads to Success The project, managed by Shepherd Tshalibe from Brown Engineering, was completed in record time, starting in mid-May 2024 and reaching completion by the end of July.

The responsibilities were divided strategically:

– Total Property Solutions (TPS): Acted as the main contractor, overseeing all civil works, including foundations,

concrete slab, and brickwork.

– Brown Engineering: Appointed as the steel contractor based on a TPS recommendation, Brown Engineering

played a crucial role in several key aspects:

– Design, fabrication, and installation of the ingenious interlocking tri-frame roof trusses, including the longest truss at 21 meters connected to a 1.3-meter-deep girder.

– Chromadek roofing and wall cladding, incorporating skylights for natural light.

– Supplying and subcontracting the installation of the large roller shutter doors to M and C Engineering.

– Project management for their portion of the project, ensuring seamless coordination with other involved parties and their factory.

A Testament to Innovation and Collaboration

The innovative design is evident in the final structure. Delivered raw materials will now enter through the north gate, off-loaded by forklifts into the receiving bay, and then transferred to the existing factory on the east side as needed. Finished products are stored in the newly constructed warehouse space.

This successful collaboration between Brown Engineering and TPS has resulted in a state-of-the-art manufacturing and distribution centre for Dulux Paints in Zimbabwe. The new facility exemplifies how thoughtful design and innovation can create a space that is not only practical but also fosters a productive working environment. It’s a testament to the power of collaboration in achieving impressive results, providing Dulux with a safe, efficient, and well-designed space to meet their growing needs.

From: S&D ISSUE 68